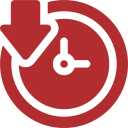

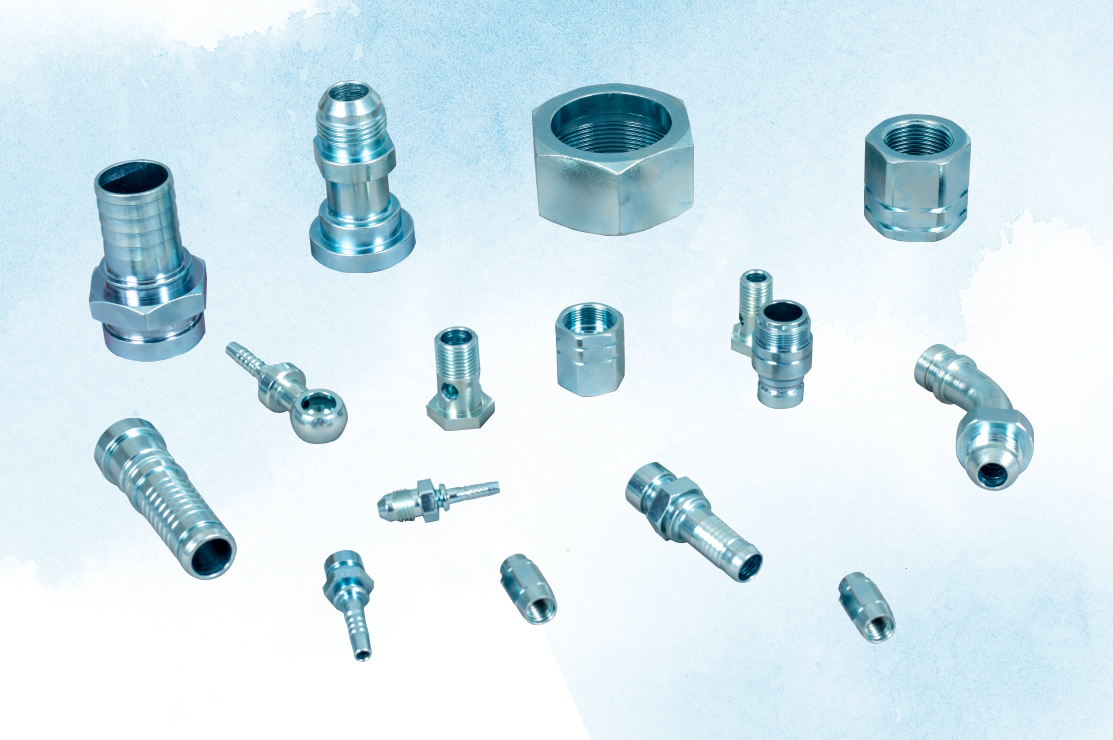

At UNIFLEX ®, we take pride in our world-class Electroplating Facility, dedicated to providing top-notch surface coating solutions. Our facility boasts cutting-edge technology and environmentally friendly processes, ensuring superior quality and performance in every finish.

Our facility is equipped with state-of-the-art equipment for Alkaline ROHS Compliant Zinc Plating. This process utilizes environmentally friendly Cr 3 passivation, resulting in finishes that are both sustainable and high performing. With a daily capacity of 30,000 sq. inches in Rack or 3000 Kgs in Barrel, we can meet the demands of high-volume production while maintaining stringent quality standards.

To address specific customer requirements and exceed OEM standards, we also have a Zinc Nickel Plating line. This advanced plating process offers enhanced corrosion resistance, surpassing 700 hours to Red Rust. By incorporating Zinc Nickel Plating into our repertoire, we ensure that our customers receive surface coatings that provide superior durability and protection against harsh environmental conditions.

Our Plating Plant is fully supported by a state-of-the-art laboratory equipped with precision measuring equipment. Salt Spray Tests are conducted using world-class WEISS Salt Spray Test Equipment under ASTM B117-03 and UNI ISO 9227 standards. This rigorous testing process ensures that our surface coatings meet the highest quality and performance standards, providing our customers with peace of mind and confidence in our products. At UNIFLEX ®, we are committed to delivering surface coating solutions that not only meet but exceed industry standards.

Our Electroplating Facility prioritizes environmental sustainability, utilizing processes and materials that minimize environmental impact while delivering exceptional performance. By investing in cutting-edge technology, stringent quality control measures, and continuous improvement initiatives, we strive to set new benchmarks in surface coating excellence.

UNIFLEX ® has now developed UNICOAT, a new generation Zinc Plating technology based on trivalent passivation and a special topcoat. delivering significantly higher levels of corrosion resistance on carbon steel fluid conveyance products far exceeding SAE J514 requirements. UNICOAT parts when tested under ASTM B117-03 and UNI ISO 9227 Standards exceed 500 Hours of corrosion prevention in Salt Spray Fog to White Rust and 1000 Hours of corrosion prevention to Red Rust.

Prolonged duration of life

Lower maintenance cost

Improved appearance

Reduced downtime

Zinc Nickel Plating

Zn+Biue Passivation

Zn+Iredesant Passivation

Feel free to reach out to us via phone or by filling out the contact form below. Our dedicated representatives are committed to providing prompt and personalized assistance to meet your needs.

We value your interest in UNIFLEX® and look forward to hearing from you. Whether you have questions about our products, need assistance with a project, or want to explore partnership opportunities, our team is here to help.

+91-80-43580300/43580301

+91-80-43580331