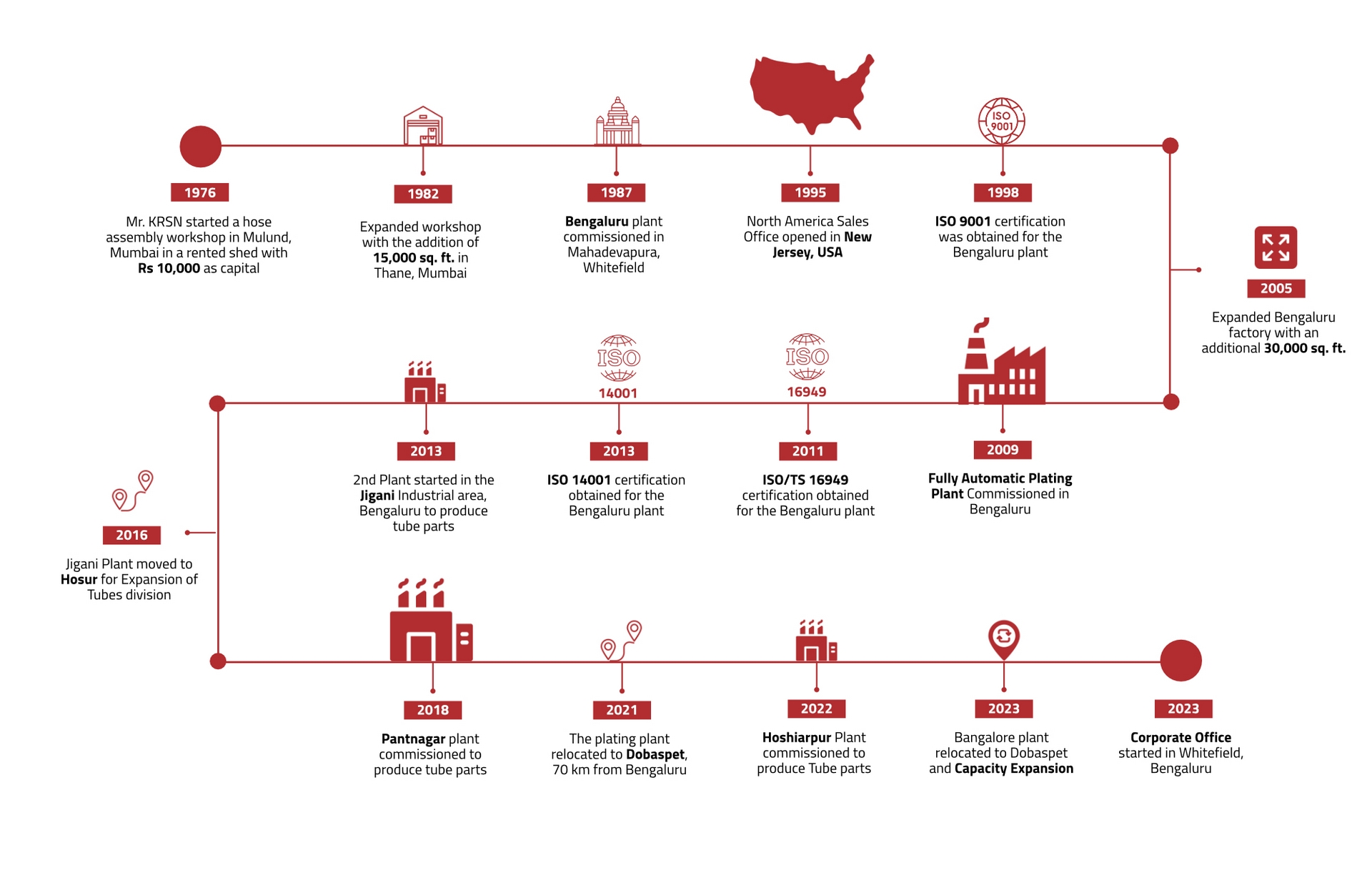

UNIFLEX®, renowned for its excellence in manufacturing, operates two distinct divisions: the Hose Products Division and the Tube Products Division, each boasting state-of-the-art facilities and cutting-edge technologies. In essence, both divisions exemplify UNIFLEX® ‘s unwavering commitment to excellence, pushing the boundaries of possibility in hose and tube manufacturing.

Located in Dobaspet near Bangalore, this division

encompasses two sprawling manufacturing plants. Equipped with sophisticated CNC

Sliding Head Turning Centers, CNC Turning & Turn Mill Centers, VMC, a Hose

Assembly Shop, a Continuous Belt Type Conveyor Furnace, and a PLC Controlled

Fully Automatic Plating Plant, it stands at the forefront of innovation.

At the heart of its operations lies a Design and

Development Centre, empowered with advanced CAM, CAD, and 3D capabilities.

Here, a dedicated team works tirelessly to craft world-class products,

specializing in Low, Medium, and High-Pressure Hose Assemblies. Materials

ranging from NAB, Titanium & Stainless Steel are expertly utilized to meet

the most demanding Marine requirements.

Spanning manufacturing plants in Hosur, Pantnagar

& Hoshiarpur, the Tube Products Division is a beacon of precision

engineering. With a robust arsenal including Multi-axis Tube Bending Machines,

End Forming Machines, Brazing facilities including advanced welding

technologies, it excels in producing tube assemblies both in low and high

volume.

From steel to copper, the division offers a diverse range of materials, catering to industries with varying demands. Whether crafting Fuel Injection Pipes (FIPs), precision CNC Laser cut fabrications, or intricate welded assemblies, UNIFLEX®Tube Products Division remains synonymous with outstanding quality and innovation.

UNIFLEX® is committed to providing superior, cost-effective quality products and services to meet or exceed customer expectations and will strive to achieve environmental & safety commitment through: